sel 451 instruction manual

Welcome to the SEL-451 Instruction Manual. This guide provides essential information for installing, configuring, and operating the SEL-451 Protection, Automation, and Bay Control System.

It ensures safe and effective use of the device, covering key features, safety precautions, and setup procedures. Read carefully before proceeding with installation or operation.

1.1 Overview of the SEL-451 Protection, Automation, and Bay Control System

The SEL-451 is a multifunctional device designed for advanced feeder protection, automation, and substation bay control. It integrates comprehensive protection, monitoring, and control capabilities into a single unit, ensuring efficient and reliable operation.

Featuring synchronized phasor measurement (IEEE C37.118 compliant), the SEL-451 provides real-time insights into system stability and voltage/current phasors. It supports up to 32 channels (VX-451 model), enabling scalable configurations for various substation requirements.

With seamless integration with circuit breakers and disconnect switches, the SEL-451 offers streamlined control and automation. Its advanced architecture supportsbay settings, mirrored bits, and customizable configurations, making it a versatile solution for modern power systems.

1.2 Importance of Reading the Manual

Reading the SEL-451 instruction manual is crucial for safe and effective operation. It provides detailed guidelines for installation, configuration, and troubleshooting, ensuring compliance with safety standards and optimal device performance.

The manual contains essential information on handling precautions, system requirements, and operational procedures. Familiarizing yourself with its contents helps prevent errors and potential damage to the equipment or connected systems.

By following the manual, users can unlock the full potential of the SEL-451, leveraging its advanced features and ensuring reliable protection and automation in substation environments. Always refer to the manual before performing any maintenance or operational tasks.

1.3 Safety Precautions and Handling Instructions

To ensure safe operation of the SEL-451, follow all safety precautions and handling instructions. Always disconnect power before performing maintenance or repairs.

Use only approved tools and components to avoid damage or malfunction. Properly ground the system to prevent electrical hazards and ensure reliable performance.

Handle batteries and charging devices with care, adhering to disposal guidelines. Avoid exposing the device to extreme temperatures or humidity, as this may compromise its functionality.

Strictly follow the manual’s guidelines to prevent personal injury or equipment damage, ensuring optimal system operation and longevity.

Key Features and Benefits of the SEL-451

The SEL-451 offers advanced feeder protection, substation bay control, and synchronized phasor measurement, ensuring comprehensive system monitoring and control in a single device.

2.1 Advanced Feeder Protection and Substation Bay Control

The SEL-451 provides comprehensive protection for feeders and substation bays, integrating advanced automation and control functionalities. It ensures reliable operation by monitoring feeder health and managing bay control seamlessly.

With built-in logic for circuit breaker status and trip targets, the device offers precise control over substation operations. Its ability to integrate with circuit breakers and disconnect switches enhances system reliability and operational efficiency.

Advanced feeder protection includes detection of faults and anomalies, while bay control ensures coordinated switching and isolation. This dual capability makes the SEL-451 a robust solution for modern substation automation needs.

2.2 Synchronized Phasor Measurement (IEEE C37.118 Compliance)

The SEL-451 supports synchronized phasor measurement, adhering to IEEE C37.118 standards. This capability provides precise time-synchronized voltage and current measurements, essential for power system stability analysis.

By enabling real-time monitoring of phasors, the device helps in assessing system dynamics and maintaining grid reliability. Its compliance with industry standards ensures accurate and reliable data for advanced applications.

2.3 Integration with Circuit Breakers and Disconnect Switches

The SEL-451 seamlessly integrates with circuit breakers and disconnect switches, enabling comprehensive control and automation of substation equipment; This integration ensures efficient operation and monitoring of electrical systems.

The device supports advanced logic for circuit breaker status and control, providing real-time updates and operational flexibility. Its ability to communicate with these components enhances system reliability and simplifies maintenance procedures.

2.4 Support for Up to 32 Channels (VX-451 Model)

The VX-451 model of the SEL-451 supports up to 32 channels, divided into two groups for flexible configuration. This allows for efficient monitoring and control of multiple substation components simultaneously.

With advanced channel management, users can assign specific functions to each group, ensuring optimal system performance. The device also supports up to 512 channels on other models, offering scalability for larger systems.

System Requirements and Compatibility

The SEL-451 operates on compatible hardware and software, ensuring seamless integration with existing systems. It supports various communication protocols for enhanced connectivity.

Compatibility with other SEL devices and systems is guaranteed, allowing for efficient network configurations and reliable performance across industrial applications.

3.1 Hardware and Software Requirements

The SEL-451 requires a compatible host system with a minimum of 2 GHz processor and 4 GB RAM for optimal performance. Ensure the system runs on a supported operating system, such as Windows or Linux.

Software compatibility includes the latest versions of SEL configuration tools. The device supports communication protocols like DNP3 and Modbus for seamless integration with existing infrastructure.

A CD manual is provided for installation guidance, and a printer is recommended for hard-copy configurations. Ensure all hardware components meet specified standards for reliable operation.

Regular software updates are essential for maintaining functionality and security. Verify compatibility with other SEL devices to ensure a cohesive system setup.

3;2 Compatibility with Other SEL Devices and Systems

The SEL-451 is designed to integrate seamlessly with other SEL devices, ensuring a unified network for protection, automation, and control systems. It supports communication with SEL relays, such as the SEL-487B, through standardized protocols like DNP3 and Modbus.

Compatibility extends to SEL software tools, enabling comprehensive system monitoring and configuration. The VX-451 model, with up to 32 channels, can be synchronized with other SEL devices for enhanced functionality.

Ensure all connected devices are updated to the latest firmware for optimal performance and compatibility. This ensures a cohesive system operation across all integrated components.

Installation and Setup

Begin with the pre-installation checklist to ensure all requirements are met. Install the SEL-451 in manual mode for initial setup. Follow safety guidelines for first power-up.

4.1 Pre-Installation Checklist

Before installing the SEL-451, ensure all system requirements are met. Verify hardware compatibility and software versions. Check power supply specifications and environmental conditions. Ensure proper grounding and wiring. Review safety precautions to avoid damage or injury. Familiarize yourself with the manual and manufacturer guidelines. Confirm the availability of necessary tools and documentation. Ensure the installation area is clean and accessible. Verify communication ports and settings. Confirm the device is in manual mode for initial setup. Ensure all circuit breakers and disconnect switches are in the correct state. Follow all safety protocols to prevent equipment damage or personal harm.

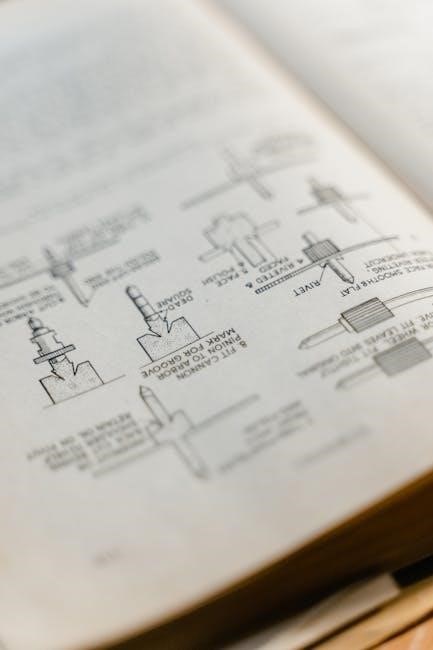

4.2 Step-by-Step Installation Guide

Mount the SEL-451 device in a secure, accessible location. Connect the power supply, ensuring proper voltage and grounding. Wire the inputs and outputs according to the system requirements. Configure communication ports for DNP3 or other protocols. Install and connect any additional hardware, such as circuit breakers or disconnect switches. Power up the device and perform a self-test to ensure functionality. Use the front panel or software to complete initial configurations. Verify all connections and settings before commissioning. Follow the manual for specific wiring diagrams and installation details. Ensure compliance with safety guidelines throughout the process. Double-check all connections for accuracy and integrity.

4.3 First Power-Up and Initial Configuration

Power up the SEL-451 device and verify the LED indicators light up; Use the front panel controls to navigate to the configuration menu. Set the date and time for accurate event logging. Configure communication ports, ensuring DNP3 settings match your system requirements. Restore custom settings from a backup file, if available. Review and confirm all configurations for accuracy. Save the settings and restart the device to apply changes. Perform a system self-test to ensure proper functionality. Refer to the manual for detailed instructions on initial setup and configuration options. Ensure all parameters align with your operational needs before finalizing the setup. This step is critical for optimal performance.

Configuration Settings

Configure default settings or customize options to meet specific requirements. Adjust DNP3 settings, bay configurations, and mirrored bits for optimal system performance and integration with other devices.

5.1 Default Settings and Customization Options

The SEL-451 comes with predefined default settings to ensure optimal performance. These settings include configurations for DNP3, ports, and bay operations, providing a smooth starting point for most applications.

Users can customize these settings to meet specific requirements. Advanced options allow modifications to alarm points, synchrophasor measurements, and control logic. The device supports tailored configurations for feeder protection and bay control.

Customization can be performed via the front-panel interface or through PC-based software tools. It is recommended to back up default settings before making changes. Refer to Section 5.2 for detailed configuration procedures.

5.2 DNP3 Configuration and Port Settings

The SEL-451 supports advanced DNP3 protocol configurations for seamless communication with other devices. Default port settings are preconfigured for ease of use, but users can customize them to suit specific network requirements.

Configuration options include setting authentication levels, defining data formats, and enabling encryption for secure communication. Port settings can be adjusted to optimize data transmission rates and ensure reliable connectivity.

Refer to Section 5.1 for additional customization options and Section 7.2 for alarm and notification configurations. Proper setup of DNP3 and port settings is critical for maintaining system stability and performance.

5.3 Bay Settings and Mirrored Bits Configuration

The SEL-451 allows for detailed bay settings configuration to manage substation automation effectively. Users can define bay names, labels, and associated parameters to streamline operations. Mirrored bits configuration ensures redundancy and fail-safe communication between devices.

Mirrored bits enable synchronization of control signals across multiple units, enhancing system reliability. Proper setup of bay settings and mirrored bits is crucial for maintaining seamless substation control and minimizing downtime.

Refer to the manual for step-by-step guidance on configuring these settings to optimize your substation automation and control systems.

Operation and Control Modes

The SEL-451 operates in Manual, Autosynchronizer, and Remote modes, offering flexible control options. Manual mode allows local control, while Autosynchronizer optimizes synchronization processes for enhanced efficiency.

6.1 Manual Mode Operations

The SEL-451 Manual Mode allows direct local control of the device, enabling operators to perform specific functions without automated interference. To activate Manual Mode, press the MANUAL push button on the faceplate. This mode is ideal for troubleshooting, testing, or when local intervention is required. While in Manual Mode, the relay displays real-time system parameters and alarm points, which can be scrolled manually or automatically. Operators can also configure settings and test functionalities without affecting the system’s operational state. Manual Mode ensures precise control, making it essential for maintenance and diagnostic tasks. Always follow safety guidelines when operating in this mode.

6.2 Autosynchronizer Functionality

The SEL-451 features an Autosynchronizer function designed to streamline operations and maintain system consistency. This function automatically synchronizes settings and ensures alignment across connected devices, reducing manual intervention. During power-up or configuration changes, the Autosynchronizer validates and updates parameters to prevent discrepancies. It is particularly useful in complex systems with multiple components, ensuring seamless communication and coordination. The Autosynchronizer enhances reliability by minimizing errors caused by manual adjustments. Operators can rely on this feature to maintain system stability and efficiency, especially in dynamic environments. Proper configuration and understanding of its operation are essential for maximizing its benefits and ensuring optimal system performance.

6.3 Local vs. Remote Control Capabilities

The SEL-451 offers both local and remote control capabilities, providing flexibility in system management. Local control allows direct operation through the device’s interface, ideal for on-site interventions. Remote control enables monitoring and command execution from a centralized location, enhancing efficiency for distributed systems. The device supports secure remote access, ensuring reliable operation without physical presence. Operators can switch between modes seamlessly, depending on operational needs. This dual capability ensures adaptability for various applications, from small substations to large, interconnected systems. Proper configuration and authorization are essential for secure remote operations, maintaining system integrity and safety. This feature-rich control system maximizes operational efficiency and responsiveness.

Monitoring and Alarm Systems

The SEL-451 provides real-time monitoring of system parameters and displays up to 66 alarm points. Alarms automatically appear in manual or autoscrolling mode for quick response.

7.1 Real-Time Monitoring of System Parameters

The SEL-451 offers comprehensive real-time monitoring of system parameters, including voltage, current, and phase angles. This ensures precise tracking of power system performance and stability. The device supports synchronized phasor measurements compliant with IEEE C37.118 standards, providing accurate time-stamped data for system analysis. Real-time data is displayed on the LCD screen, allowing users to quickly assess system status. Additionally, the SEL-451 can monitor up to 32 channels, enabling detailed oversight of complex substation configurations. This feature-rich monitoring capability helps utility professionals maintain system reliability and respond promptly to potential issues.

7.2 Alarm Points and Notification Systems

The SEL-451 includes an advanced alarm system that monitors up to 66 alarm points, ensuring timely notifications of critical events. The relay automatically displays new alarms in both manual and autoscrolling modes, simplifying monitoring. Customizable alarm settings allow users to define thresholds and priorities, enhancing system reliability. Notifications can be configured to alert operators through various communication channels, ensuring prompt responses to issues. This robust alarm system is essential for maintaining substation reliability and minimizing downtime, providing clear and actionable alerts for efficient troubleshooting and resolution.

7.3 Synchrophasor Measurement and Analysis

The SEL-451 supports synchronized phasor measurements compliant with IEEE C37.118, providing real-time insights into system stability. It measures voltage and current magnitudes and angles, enabling precise analysis of power system dynamics. These measurements are essential for assessing grid stability and detecting potential issues. The device displays primary phase voltages (VA, VB, VC) in both Y and Z configurations, ensuring comprehensive monitoring. This functionality enhances diagnostic capabilities and supports advanced power system applications, making it a critical tool for maintaining grid reliability and performance. The SEL-451’s synchrophasor measurements are integral to modern power system operations and analysis.

Maintenance and Troubleshooting

Perform routine maintenance to ensure optimal performance. Check for firmware updates and install them as needed. Use diagnostic tools to identify and resolve faults quickly.

8.1 Routine Maintenance Procedures

Regular maintenance is crucial for the SEL-451 system to function optimally. Start by inspecting the device for any physical damage or wear. Clean dust and debris from the exterior and internal components using compressed air. Verify all connections are secure and free from corrosion. Check the firmware version and update if necessary to ensure compatibility and access to new features. Backup configuration settings before performing any updates. Additionally, review system logs to identify recurring issues and address them promptly. Schedule maintenance during low-traffic periods to minimize operational disruptions. Always refer to the manual for specific guidance on handling sensitive components and software updates. This proactive approach ensures reliability and extends the lifespan of the SEL-451 system. By following these steps, users can maintain peak performance and avoid potential downtime. Routine checks also help in identifying and resolving minor issues before they escalate into major problems. Regular maintenance is essential for sustaining the integrity and efficiency of the SEL-451 Protection, Automation, and Bay Control System. Always adhere to the manufacturer’s guidelines for the best results. This ensures seamless operation and compliance with safety standards. Proper care and attention will keep the system running smoothly for years to come.

8.2 Diagnostics and Fault Identification

Diagnostics and fault identification are critical for maintaining the SEL-451 system’s reliability. Begin by reviewing system logs to identify error codes or unusual activity. Utilize the device’s LED indicators to detect issues such as power faults or communication errors. Check alarm points for specific fault conditions, as the SEL-451 can display up to 66 alarms. Use the autosynchronizer functionality to verify synchronization status and system stability. For complex issues, refer to the manual’s troubleshooting section, which provides detailed fault trees and solutions. Regularly inspect connections and ensure firmware is up-to-date to prevent compatibility issues. Isolate problems by testing individual components or configurations. Always follow safety guidelines when performing diagnostics to avoid further complications. This systematic approach ensures timely resolution of faults, minimizing downtime and ensuring optimal performance. Proper fault identification is essential for maintaining the integrity of the SEL-451 system. By leveraging built-in tools and adhering to diagnostic procedures, users can efficiently address and resolve issues. Regular diagnostics also help prevent potential failures before they occur, ensuring continuous operation. Always consult the manual for specific instructions tailored to the SEL-451’s advanced features. This ensures accurate and safe troubleshooting practices.

8.3 Firmware Updates and Software Management

Firmware updates and software management are crucial for ensuring the SEL-451 operates with the latest features and security patches. Regularly check the manufacturer’s website for updates and follow the provided instructions carefully. Before updating, backup configuration settings to prevent data loss. Use compatible software tools to download and install firmware, ensuring the system is powered on and connected to a reliable power source. After installation, verify the update by checking the version number in the device’s interface. Avoid interrupting the update process, as this could cause system instability. If issues arise, consult the troubleshooting guide or contact technical support. Keep software management tools updated to maintain compatibility with the SEL-451. This ensures seamless performance and access to new functionalities. Proper firmware management is essential for optimizing the SEL-451’s performance and security.

Technical Specifications and References

This section details the SEL-451’s electrical, environmental, and compliance specifications, ensuring compatibility and adherence to industry standards, with additional resources for further technical information.

9.1 Electrical and Environmental Specifications

The SEL-451 operates within a voltage range of 115/230 VAC (±10%) and supports nominal currents of 1A/5A. It is designed for environments with temperatures between -40°C and +85°C and humidity up to 95% non-condensing. The device meets IEEE C37.118 standards for synchrophasor measurements, ensuring precision in real-time system monitoring. It is housed in a rugged enclosure rated NEMA 4X, suitable for harsh industrial conditions. For storage, the unit can withstand temperatures from -55°C to +105°C. Compliance with international standards ensures reliability and safety. Always refer to the manual for detailed specifications and operating conditions to ensure optimal performance and longevity of the device.

9.2 Compliance and Certification Information

The SEL-451 is designed to meet or exceed industry standards for safety, performance, and environmental compliance. It adheres to IEEE C37.118 standards for synchrophasor measurements, ensuring accurate and reliable data. The device is UL-certified and complies with IEC 60255 standards for electrical safety in industrial environments. Additionally, it meets NERC and ANSI/IEEE standards for power system reliability. The SEL-451 is also RoHS compliant, reflecting its commitment to environmental sustainability. These certifications ensure the device operates safely and efficiently in various global applications. Always verify compliance with local regulations before deployment. For detailed certification information, refer to the technical specifications section or contact SEL support.

9.3 Additional Resources and Documentation

For further assistance, refer to the SEL-451 Instruction Manual available on the SEL website or the provided CD. A printed manual can be requested directly from SEL. Additional resources include technical specifications, data sheets, and configuration guides. Contact SEL support at 1.509.332.1890 or visit their website for comprehensive documentation. These resources provide detailed insights into system operation, configuration, and compliance. Ensure to review all materials for optimal device utilization and troubleshooting. For specific queries, reach out to SEL’s customer support team. Additional documentation covers advanced features, maintenance procedures, and compliance details, ensuring comprehensive understanding of the SEL-451 system.

The SEL-451 Instruction Manual provides comprehensive guidance for optimal device utilization. Follow safety precautions, configuration tips, and maintenance routines for reliable performance and system stability.

10.1 Summary of Key Features and Benefits

The SEL-451 offers advanced feeder protection and bay control, synchronized phasor measurements, and seamless integration with circuit breakers. It supports up to 32 channels, ensuring robust monitoring and control.

Its compliance with IEEE C37.118 standards enhances system stability insights. The device provides real-time monitoring, alarm systems, and diagnostics for efficient troubleshooting. Customizable settings and firmware updates ensure adaptability and longevity.

By integrating automation and protection in one unit, the SEL-451 streamlines substation operations, reducing complexity and improving reliability. These features make it a versatile solution for modern electrical systems.

10.2 Final Tips for Effective Use of the SEL-451

Regularly update firmware and software to ensure optimal performance and security. Always follow safety guidelines when handling electrical components to prevent damage or injury.

Utilize the autosynchronizer feature for streamlined operations and minimize manual intervention. Leverage real-time monitoring and alarm systems to proactively address potential issues.

Customize settings to align with specific system requirements for enhanced functionality. Refer to the manual for troubleshooting and configuration guidance to maximize efficiency.

Schedule routine maintenance to maintain reliability and extend the lifespan of the device. By adhering to these tips, users can ensure the SEL-451 operates at its full potential.

Leave a Reply

You must be logged in to post a comment.